Farm & Ranch

[AgriLife Today] AgriLife experts discuss fumonisin contamination, possible avoidance practices

By: Kay Ledbetter

Writer: Kay Ledbetter, 806-677-5608, [email protected]

Contact: Dr. Tom Isakeit, 979-862-1340, [email protected]

Dr. Wenwei Xu, 806-746-6101, [email protected]

AMARILLO – Texas A&M AgriLife officials are offering some best management practices for producers to keep in mind as harvest continues and for next year after fumonisin contamination has been found in truckloads of corn across the Texas High Plains.

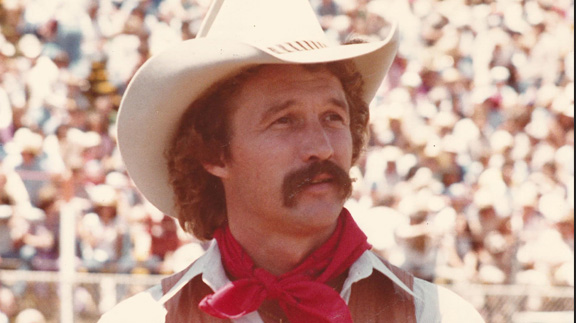

Dr. Tom Isakeit, Texas A&M AgriLife Extension Service plant pathologist in College Station, spent several days collecting samples in the High Plains for fumonisin contamination testing. (Texas A&M AgriLife photo by Dr. Jourdan Bell)

Dr. Tom Isakeit, Texas A&M AgriLife Extension Service plant pathologist in College Station, said this year nothing can be done to minimize fumonisin already present in the standing crop; however, producers can make a few changes during harvest to possibly reduce the amount of contaminated grain collected.

“You can adjust the combine settings to kick out the smaller grain kernels that tend to have much higher levels of contamination of fumonisin,” Isakeit said.

Fumonisin toxin is produced when certain Fusarium fungi are present on the corn, although not all Fusarium-infected kernels will have fumonisin, he said. The only way to know if the toxin is present is to have a chemical test run.

But there are visible symptoms of the fungal infection, including a white discoloration of the kernels, and when they dry down they will be smaller or lighter than the healthy kernels, Isakeit said.

The severity can be lessened by cleaning the seed or separating the damaged kernels out, he said. Sometimes just a few kernels can cause the higher concentrations. And though it is not done much in Texas, artificially drying the corn from a high moisture of 24 percent to 15 percent in a 24-hour period can also minimize contamination. Optimum levels of fumonisin production occur between 18-20 percent moisture.

Also, producers should segregate portions of the field if there was moisture stress, keeping corn from the drought-stressed areas of the field separate from the rest of the field, Isakeit said.

“The worst damage generally occurs around the edges of the field,” he said. “What you find on the outside for fumonisin contamination might not be what you find in the middle of the field.”

Dr. Wenwei Xu, Texas A&M AgriLife Research corn breeder in Lubbock, examines a field of corn in the southern High Plains of Texas for Fusarium fungus disease. (Texas A&M AgriLife photo by Dr. Jourdan Bell)

Isakeit also warned that putting corn into storage won’t get rid of the fumonisin contamination, but high levels of moisture or some leakage after placement in bins can add to the problem.

“For storage, you want to have your corn dry and keep it dry,” he said. “Make sure the bins are operated properly and are well ventilated.”

Beyond this year, Isakeit and Dr. Wenwei Xu, Texas A&M AgriLife Research corn breeder in Lubbock, offered some management practices that could help possibly control the problem in the future.

Both said there is no product available that can be applied to prevent fumonisin, so minimizing the contamination in the future will require a combination of hybrid selection and cultural practices.

Isakeit said producers should pay close attention to any hybrid differences out in fields this year, adding “that might be the very least we can do now.”

Xu said there is a clear difference in terms of Fusarium fungus infection among hybrids, and there is a clear difference in terms of susceptibility to common smut.

Resistance to Fusarium fungus disease, common smut and earworm damage are all factors that should play into hybrid selection, he said.

“If a hybrid is susceptible to these, it doesn’t mean every field will be severe, but it can be elevated in bad years and the kernel damage under different environmental conditions can lead to more contamination,” Xu said.

“Based on my observations and conversations with farmers, you can find the problem in both dryland and irrigated corn and short-season to full-season corn,” he said. “It varies from field to field, and the hybrid, growth management, hot temperatures and drought stress will determine the severity.

“Farmers need to be paying attention to the factors that contributed to high fumonisin contamination this year when selecting their hybrid next year,” Xu said.

Hybrids less prone to loss of kernel integrity should be planted, Isakeit said.

In 2008, there was an outbreak of fumonisin in this the High Plains and loss of kernel integrity was associated with hybrids that had problems with contamination, according to Dr. Gary Odvody, AgriLife Research plant pathologist, Corpus Christi. This loss of kernel integrity was seen in hybrids with high yield potential when they were subjected to late-season stress.

Insect resistance, including that in transgenic hybrids, can help reduce contamination by reducing wounds in the kernels that allow entry of the fungus.

Also, he said other factors in fumonisin contamination are the common smut disease, which can act as a sponge and retains moisture in the ear, allowing the Fusarium fungus to grow and produce toxin; and hybrids with ears that remain standing instead of falling at maturity, which retains moisture and prevents the ear from drying down.

Some other crop management strategies he outlined are:

– Control weeds to reduce moisture stress.

– Optimize irrigation to avoid stress between flowering and grain fill.

– Maintain optimal nitrogen fertility, especially with high plant populations.

For more information, go to http://aflatoxin.tamu.edu/ or http://www.cornmycotoxins.com.

-30-

Find more stories, photos, videos and audio at http://today.agrilife.org

Farm & Ranch

What to expect when your cow’s expecting

Overweight cattle and cattle turned out on lush legumes with high concentration are at risk as well. In this case, an epidural anesthetic is usually necessary. The tissue will need to be replaced and sutured in place. Vaginal sutures will need to be removed prior to calving.

Toxemia happens when cattle are exposed to low nutrition during the last two months of pregnancy. Cows that are overly fat and/or carrying twins are at higher risk. Cows with toxemia become depressed, stop eating and often stand off away from the herd. You will notice some have the scent of acetone on their breath. As the condition worsens, the cow may develop muscle tremors. Treatment for toxemia is IV glucose, B vitamins or propylene glycol given by oral drench.

During calving there are a number of problems that could occur. Those include dystocia, bruises and lacerations to the birth canal, uterine prolapse, milk fever, retained placenta and grass tetany.

According to the Beef Cattle Handbook, a product of Extension Beef Cattle Resource Committee Adapted from the Cattle Producer’s Library, at any time a cow is unable to deliver her calf, a dystocia has occurred. There are many things a producer can do to reduce this incidence. With heifers, lot those with small pelvic areas before breeding. Select bulls based on their birth weight, not on their relative size. Ultimately use bulls that will produce small birth-weight calves. When calving first-calf heifers separate them from cows, at best into small groups. Producers will want to provide surveillance over the heifers on a 24 hour basis. Some tips include restricting the calving to 42 to 60 days. That will enable personal focus for a short, intense calving period. Also feeding at night between 9 and 11 p.m. will cause more animals to calve during daylight hours.

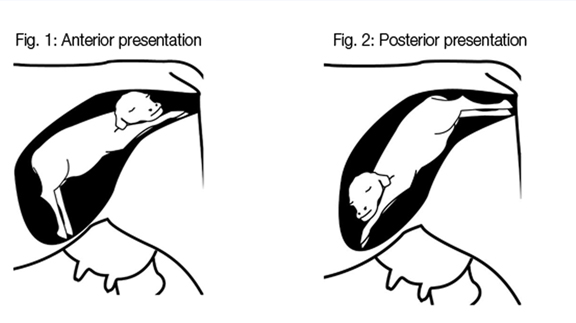

If problems arise and a cow hasn’t shown progress in 60 to 90 minutes, it’s time for the producers to step in. Signs of an abnormal delivery are the head only, the head and one leg, one leg alone or the tail. At this point it is best to contain the animal in a squeeze chute or small pen. A calf can only deliver one of two ways: both front feet followed by the head or both back feet out together. Once constrained, using ample lubrication, a producer can reach in and move the calf to one of the two correct positions. If unable to do so, a veterinarian should be called. The top problems include not getting the head out with front feet, having a calf too big to deliver through the mother’s birth canal resulting in hip lock and abnormal breach in which the tail is the only part of the calf visible through the vulva. If all goes well and pulling the calf is suggested, direct traction down and away from the birth canal. Do not pull straight out behind the cow. If two men are unable to pull the calf using the OB chains or when using the calf puller, do not use excessive force. It will not deliver the calf. Odds are the cows birth canal is too small for the calf and will result in a c-section.

Keep in mind bruises, lacerations and rupture of the birth canal are possible during a difficult birth. Rough handling of the calf or maternal tissues and careless use of obstetrical instruments during calving add danger. This is typical when a cow is in labor several hours with a dry, non-lubricated birth canal.

Cows with difficult delivery and trauma to the tissue and birth canal may have damage to the nerves and spinal cord or hips that supply the legs. This results in abnormal leg function. In some cases, while pulling a calf, excessive force was used and the middle lower pelvis bones were fractured. At this point steroids are administered to help with swelling and nerve healing. In bad cases were the cows are unable to stand, they need to be hoisted to their feet twice a day.

In older cows producers may see difficulty in birth injury or irritation of the external birth canal and severe straining, retained placenta and loose uterine attachment in the abdominal cavity called uterine prolapse. When noticed, this condition needs immediate action. Apply material to uterine wall to saturate fluid ASAP. You can use sulfaurea powder, urea powder or even sugar. Replace the uterus immediately or call your veterinarian. Without properly replacing the uterine horns, prolapse will reoccur.

Usually the placenta is passed in three to eight hours. If the placenta hasn’t passed in eight to 12 hours of calving, the placenta is retained and the cows must be treated. A number of reasons lead to retained placenta: dystocia, c-sections, fetotomy, twinning or abortion along with other infectious diseases. Even feed deficiencies, malnutrition, low carotene, vitamin A, iodine, selenium and vitamin E can be to blame. To treat, use slight, manual force and gently pull on the placenta. If it resists, stop and pack the uterus with boluses or fluid douches to keep antibiotics in the uterus. As with prolapse, be sure to use proper hygiene when treating the uterus or worse problems will occur.

Another condition parallel with cows with age, number of calves and dairy or mixed breeds is milk fever. This condition happens when a cow starting to produce milk is unable to remove calcium from her bones quickly enough. If blood levels of calcium fall below the minimal level, the muscles of the body are unable to function. This leaves the cow almost crippled, comatose and dead. High blood levels of estrogen inhibit calcium mobilization; this may be a factor on pastures that are high in legumes. Usually a slow administer of IV calcium is given. 300 to 500 ml of a commercial calcium solution is given over 20 to 30 minutes.

Lastly, grass tetany poses as an issue to cows calving. It is similar to milk fever, but in this instance cattle have heavy post-calving lactation and lose large amounts of magnesium in their milk. Most types of mixed pasture grasses are low in magnesium. If cows are exposed to cold weather or stress during early lactation, their blood levels may drop low enough to cause grass tetany. At that point an IV of magnesium is given with calcium. Treatment is not as effective as with milk fever and in many cases, animals do not respond.

This article was originally published in the January 2016 issue of North Texas Farm & Ranch.

Farm & Ranch

Managing Show Cattle Through The Winter

By Heather Welper

Husband and wife duo, Heather and Calvin Welper, are the Co-Owners and Operators or Two C Livestock, located in Valley View, Texas.

The pair’s operation has a show cattle focus where they raise and sell purebred heifers of all breeds and club calf Hereford steers.

When it comes to show cattle, the Welpers know a thing or two including how to prepare for the cold winter months and the Texas major show season run.

To read more, pick up a copy of the November edition of North Texas Farm & Ranch magazine, available digitally and in print. To subscribe by mail, call 940-872-5922.

Farm & Ranch

Double M Ranch & Rescue

By Hannah Claxton, Editor

As the sun rises each day, so do the dozens of mouths that Meghan McGovern is responsible for getting fed. Rather than the sounds of a rooster crowing, McGovern hears the bellows and bleats of a variety of exotic deer, the chortle of kangaroos, the grunts of water buffaloes, and the chirps of a lemur.

Nestled against the banks of the Red River, the Double M Ranch and Rescue, with its high game fences and deer sprinkling the landscape,s its in stark contrast to the surrounding ranches.

“Having deer is kind of like eating potato chips- you can never actually have just one,” said McGovern with a laugh.

McGovern has several herds to take care of- fallow deer, axis deer, water buffalo, goats, and bison. In smaller numbers, there’s also a few kangaroos, a lemur, a potbelly pig, a pair of zebras, a watusi, and a few horses.

To read more, pick up a copy of the November edition of North Texas Farm & Ranch magazine, available digitally and in print. To subscribe by mail, call 940-872-5922.

-

Country Lifestyles2 years ago

Country Lifestyles2 years agoScott & Stacey Schumacher: A Growth Mindset

-

Country Lifestyles8 years ago

Country Lifestyles8 years agoStyle Your Profile – What your style cowboy hat says about you and new trends in 2017

-

HOME8 years ago

HOME8 years agoGrazing North Texas – Wilman Lovegrass

-

Outdoor10 years ago

Outdoor10 years agoButtercup or Primrose?

-

Country Lifestyles5 years ago

Country Lifestyles5 years agoAmber Crawford, Breakaway Roper

-

Country Lifestyles8 years ago

Country Lifestyles8 years agoDecember 2016 Profile, Rusty Riddle – The Riddle Way

-

Country Lifestyles9 years ago

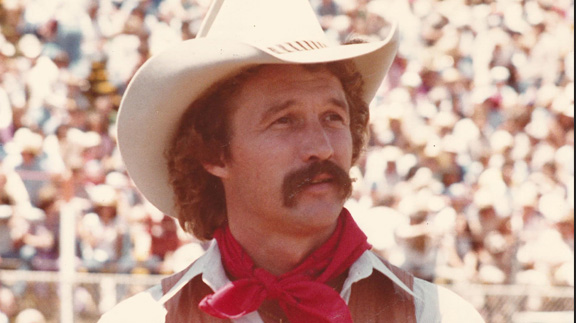

Country Lifestyles9 years agoJune 2016 Profile – The man behind the mic: Bob Tallman

-

Equine1 year ago

Equine1 year agoThe Will to Win