Farm & Ranch

[AgriLife Today] Closed-loop concept could be the future of sustainable animal farms

By: Adam Russell

- Writer: Adam Russell, 903-834-6191, [email protected]

- Contact: Dr. Eunsung Kan, 254-968-4144, [email protected]

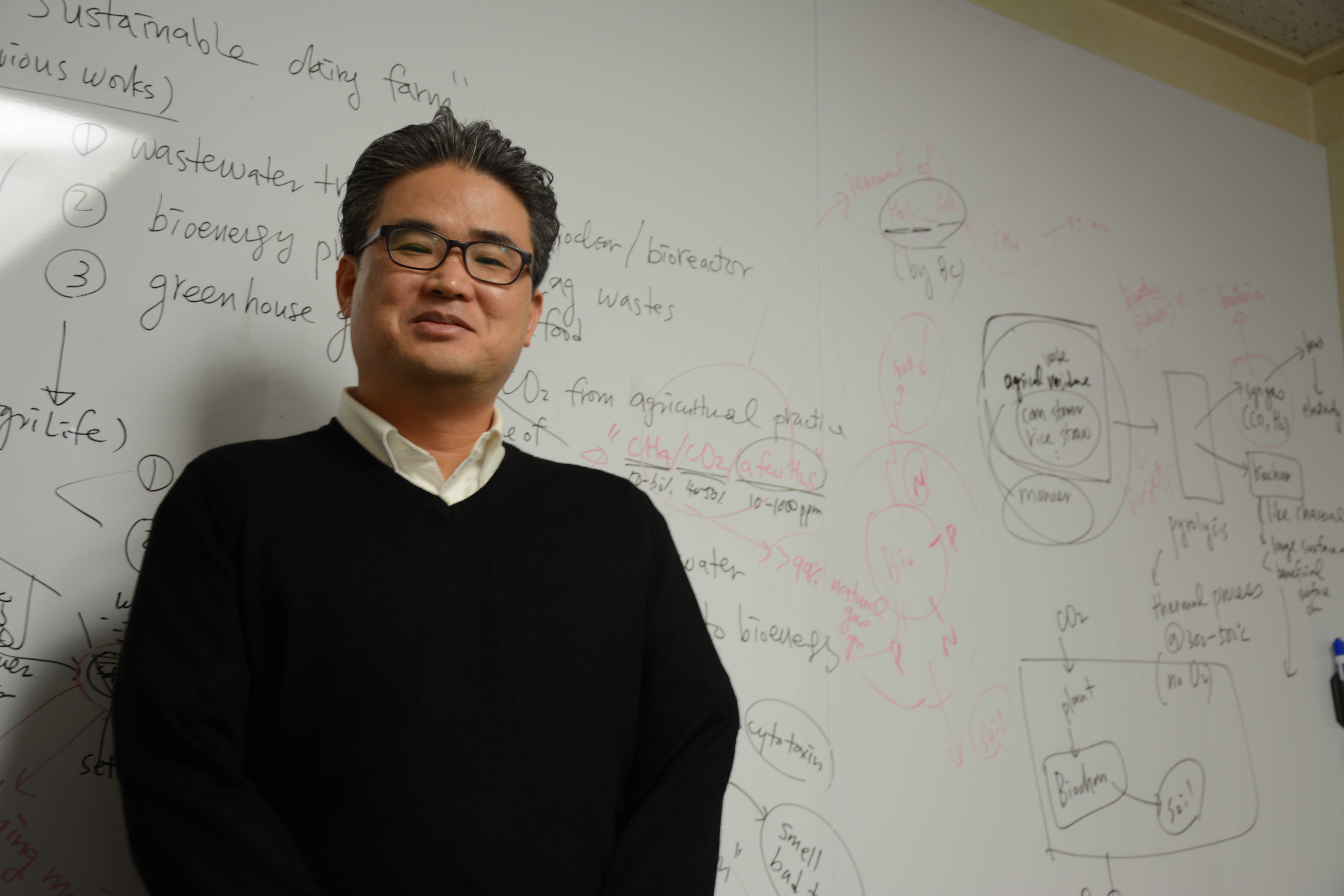

STEPHENVILLE – Dr. Eunsung Kan sees his concept of a closed-loop dairy farm, which reuses wastewater, emits zero waste and powers itself on manure, as the future of sustainable animal farming.

Kan, a Texas A&M AgriLife Research chemical and environmental engineer in Stephenville, said his concept could change the way dairies, swine and poultry farms deal with manure, wastewater and greenhouse gasses while utilizing the waste to generate electricity.

Animal waste is a blessing and curse for dairies.

Manure is sold to local farmers who need to infuse nutrients into the soil for crops and forage. However, tons of manure can also be logistically taxing as facilities keep up with the treatment and distribution of large quantities of environmentally problematic materials monitored by state and federal environmental regulators.

Farm operations have been implicated in higher-than-normal levels of nitrogen and phosphorous, antibiotics, heavy metals and hormones in surface and groundwater downstream from facilities. Manure is also a known contributor to greenhouse gas emissions, such as methane and carbon dioxide.

The U.S. Department of Agriculture Natural Resources Conservation Service estimates manure from a dairy milking 200 cows can produce as much nitrogen as is in the sewage from a community of 5,000-10,000 people.

Kan’s research would utilize existing technology – biochar, a carbon material similar to charcoal, created from animal manure and agricultural waste, such as corn stubble or rice straw – that would be used to filter solid waste and effluent. The biochar could be used as a slow-release fertilizer or converted, via pyrolysis, which is the decomposition of organic material by heat, into energy to power the farm.

The closed-loop dairy concept focuses on three main goals – wastewater treatment using dairy manure-derived biochar, producing bioenergy using dairy manure and capturing greenhouse gasses via adsorption onto dairy manure-derived biochar, Kan said.

Biochar has proven to provide a beneficial surface chemistry that can filter a wide range of contaminants, including nitrogen and phosphorous, he said. When the surface of biochar is modified with several methods in a lab, it has shown an ability to capture antibiotics, pesticides, hormones, heavy metals and other possible contaminants.

“The mission is the treatment and reuse of dairy wastewater and the conversion of dairy waste into energy to power the facility,” he said. “It focuses on providing a model for sustainable farming.”

Last year, Kan received a $1 million grant from the Texas A&M University Chancellor’s Research Initiative Fund to research the viability of the closed-loop dairy system. Before joining AgriLife Research, he also received about $400,000 in research grants from the Environmental Protection Agency, U.S. Department of Agriculture and U.S. Geologic Survey to research the concept’s potential to treat animal waste, control greenhouse gas emissions and convert manure to energy.

CONCEPTUAL SYSTEM

The closed-loop dairy is a relatively simple concept, Kan said.

Cows produce manure, which when mixed with remnants of local crops, can become a seemingly endless supply of filtering material, fertilizer and energy.

Columns filled with biochar would act as a water purification system that filters nitrogen, phosphorous and other contaminants from liquid as it passes through, Kan said.

“The affluent from the column would then be very low in nitrogen and phosphorous,” he said. “If we filter to low levels of nitrogen and phosphorus it wouldn’t cause any environmental problem.”

The biochar used to filter nitrogen and phosphorous could then be used as slow-release fertilizer that provides needed nutrients to plants and would not wash away as runoff from heavy rains. In addition, biochar immobilized with photocatalysts would decompose toxic contaminants to harmless products when irradiated by exposure to ultraviolet light.

For instance, Kan’s study has shown that a biochar immobilized with photocatalysts completely degraded antibiotic and hormone compounds while effectively controlling pathogens. The potential for biochar’s use to filter wastewater goes beyond agriculture and could be applied at any wastewater treatment plant, or even to filter contaminants in injection water used in the petroleum industry for fracking.

For energy, dairy manure would be fed into a pyrolysis reactor on site that would use relatively low heat, 500-1,000 degrees Fahrenheit, to create compressed hydrogen and carbon monoxide syngas that can be used to create electric power, Kan said. Excess electricity could be sold to local utility companies. The byproduct from pyrolysis of dairy manure is biochar.

“The principle is very simple,” Kan said. “The dairy would just need a different size reactor to meet its scale of manure output and energy needs.”

Dr. Sergio Capareda, an AgriLife Research agricultural engineer in College Station, proved the pyrolytic conversion of dairy manure to syngas and biochar from his USDA-funded project, Kan said. Kan plans to advance this concept by biologically converting syngas to butanol and bio-jet fuel as alternative transportation fuels, and developing biochar-based processes for wastewater treatment and greenhouse gas control.

Several other researchers and engineers within the Texas A&M system are collaborating with Kan, and interest in the concept is growing among public institutions and private companies.

CONCEPT TO REALITY

Kan will produce a lab-scale version of the closed-loop dairy to determine the necessary scale for application and experimentation at the neighboring Southwest Regional Dairy Center in Stephenville, a privately owned working dairy operated by Tarleton State University used for educational purposes. He hopes to have a system, including the pyrolysis reactor, operating at the dairy within three to four years.

“Having the dairy farm here provides a good opportunity for field data,” he said. “The field demonstrations will help us work out any problems that might arise at the various scales that might be applied by commercial animal farms.”

The dairy produces milk that is processed for consumption and into products such as cheese and yogurt and sold in local grocery stores.

Clay Dameron, the dairy’s waste manager, said between 300-400 cows are milked daily. Those cows produce manure and effluent that is treated via a conventional lagoon system. Around 90-130 tons of solids are moved to nearby croplands and pastures every three weeks where it’s used as fertilizer. Treated liquids from the lagoon are dispersed via sprinklers in nearby fields.

Kan said he believes the closed-loop system will prove to be a logistically and financially viable model for dairy producers to implement in the future. He expects his pilot project at the regional dairy to produce data that will draw more interest and investment from public institutions and private companies.

“It is very exciting,” he said. “I look forward to working with my collaborators and colleagues to make this concept a reality that could change the way dairies operate by providing a self-sustaining, environmentally friendly model.”

-30-

Find more stories, photos, videos and audio at http://today.agrilife.org

Farm & Ranch

Managing Show Cattle Through The Winter

By Heather Welper

Husband and wife duo, Heather and Calvin Welper, are the Co-Owners and Operators or Two C Livestock, located in Valley View, Texas.

The pair’s operation has a show cattle focus where they raise and sell purebred heifers of all breeds and club calf Hereford steers.

When it comes to show cattle, the Welpers know a thing or two including how to prepare for the cold winter months and the Texas major show season run.

To read more, pick up a copy of the November edition of North Texas Farm & Ranch magazine, available digitally and in print. To subscribe by mail, call 940-872-5922.

Farm & Ranch

Double M Ranch & Rescue

By Hannah Claxton, Editor

As the sun rises each day, so do the dozens of mouths that Meghan McGovern is responsible for getting fed. Rather than the sounds of a rooster crowing, McGovern hears the bellows and bleats of a variety of exotic deer, the chortle of kangaroos, the grunts of water buffaloes, and the chirps of a lemur.

Nestled against the banks of the Red River, the Double M Ranch and Rescue, with its high game fences and deer sprinkling the landscape,s its in stark contrast to the surrounding ranches.

“Having deer is kind of like eating potato chips- you can never actually have just one,” said McGovern with a laugh.

McGovern has several herds to take care of- fallow deer, axis deer, water buffalo, goats, and bison. In smaller numbers, there’s also a few kangaroos, a lemur, a potbelly pig, a pair of zebras, a watusi, and a few horses.

To read more, pick up a copy of the November edition of North Texas Farm & Ranch magazine, available digitally and in print. To subscribe by mail, call 940-872-5922.

Farm & Ranch

Acorn Toxicity

By Barry Whitworth, DVM, MPH

With the prolonged drought, most pastures in Oklahoma end up in poor condition. With the lack of available forage, animals may go in search of alternative foods.

If oak trees are in the pastures, acorns may be a favorite meal for some livestock in the fall. This may result in oak poisoning.

Oak leaves, twigs, buds, and acorns may be toxic to some animals when consumed.

To read more, pick up a copy of the November edition of North Texas Farm & Ranch magazine, available digitally and in print. To subscribe by mail, call 940-872-5922.

-

Country Lifestyles2 years ago

Country Lifestyles2 years agoScott & Stacey Schumacher: A Growth Mindset

-

Country Lifestyles8 years ago

Country Lifestyles8 years agoStyle Your Profile – What your style cowboy hat says about you and new trends in 2017

-

HOME8 years ago

HOME8 years agoGrazing North Texas – Wilman Lovegrass

-

Outdoor10 years ago

Outdoor10 years agoButtercup or Primrose?

-

Country Lifestyles5 years ago

Country Lifestyles5 years agoAmber Crawford, Breakaway Roper

-

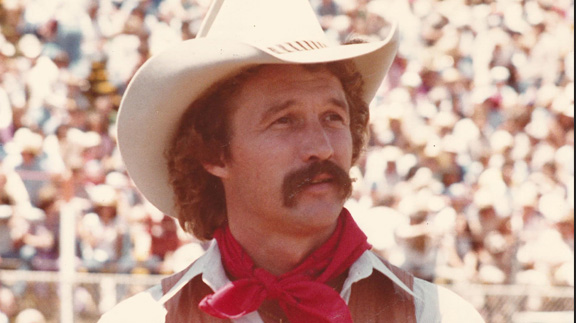

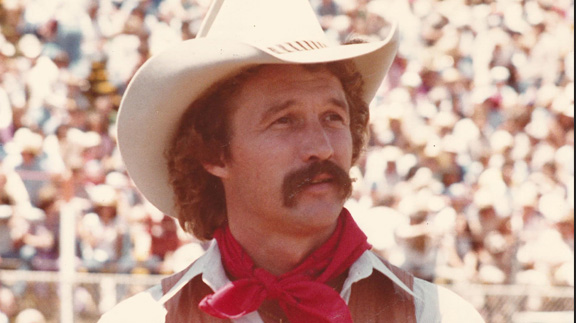

Country Lifestyles9 years ago

Country Lifestyles9 years agoJune 2016 Profile – The man behind the mic: Bob Tallman

-

Equine1 year ago

Equine1 year agoThe Will to Win

-

Country Lifestyles8 years ago

Country Lifestyles8 years agoDecember 2016 Profile, Rusty Riddle – The Riddle Way